Interview With SCODY’s Head of Design

- 17 Jan, 2026

- Home , SCODY News and Product Reviews

- 0 Comments

I was lucky enough to find time this week to sit down with SCODY’s Head of Design, Maylin Chuah, and discuss what makes SCODY’s approach to design and manufacturing so unique.

SCODY designs and manufactures in Australia. How does designing locally change the way you think about performance apparel compared to designing for overseas markets?

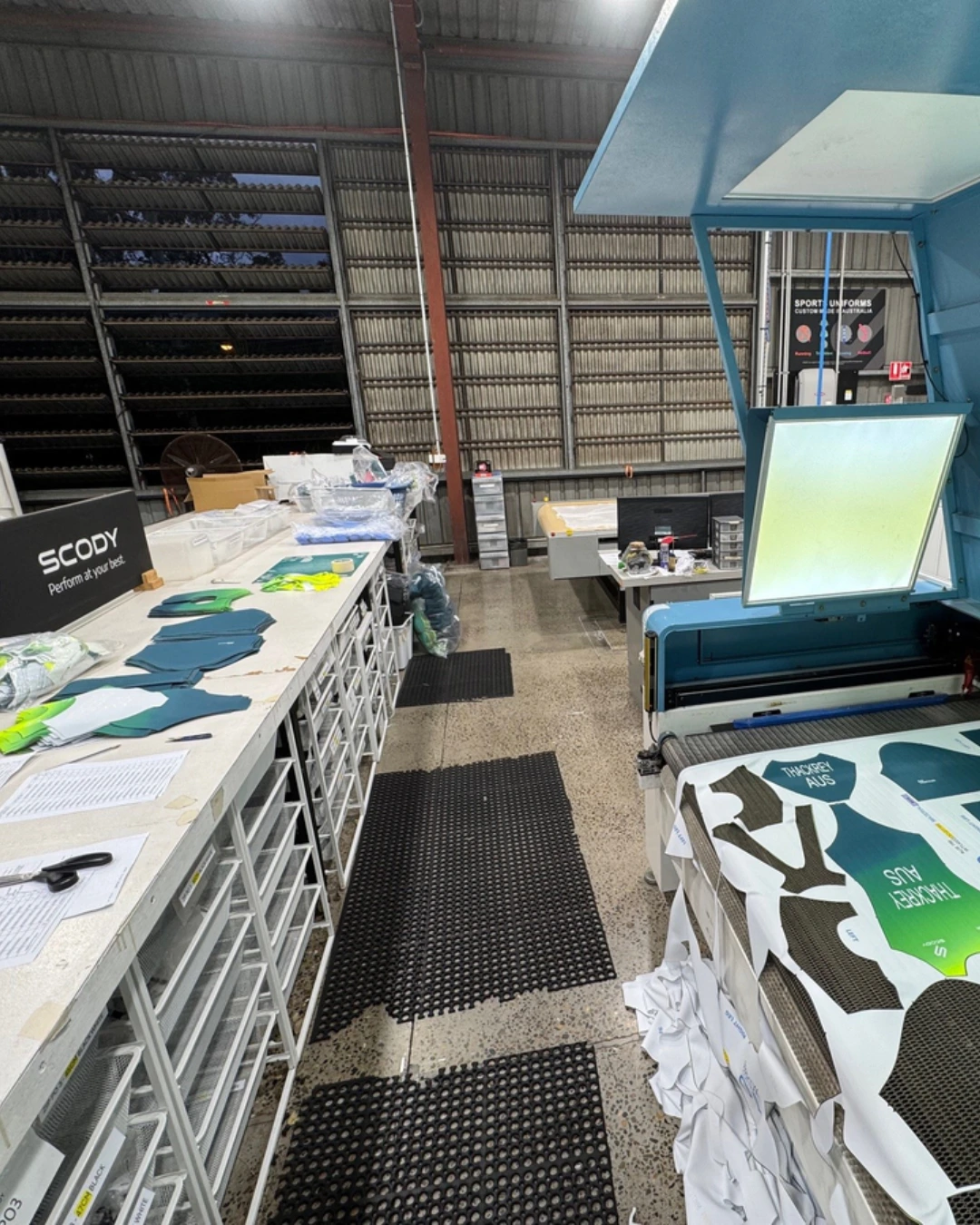

Manufacturing locally definitely gives you a sense of agility over overseas factories. If I'm developing a new sample, I can finalise a pattern, send it downstairs to the artists, print it in the factory and have it cut in a day, so in a couple of days, we have a sample. It's nice to see the whole process. We can get new samples manufactured really quickly. My previous experience in other roles with the overseas development process has definitely been a black box. I like the transparency of being able to engage with all the elements.

When you start designing a new cycling or triathlon garment, what problem are you trying to solve first: comfort, performance, durability, or something else?

I think each of those categories may be important for different customers. As we touch on later, the weather here is very hot, and the UV factor is always high. It's really important for us to ensure the safety of our athletes, but we always strive to consider comfort too.

We don’t just design for elite athletes; we make sure recreational athletes are comfortable as well. It's about comfort and performance in the activity and balancing that with the fit of the garment. We’re considering the fabric’s properties, as well as the fit of the pattern, the production needs and how that will all work together. For example, adding another panel might make it harder for production or affect the yield of the fabric, and cost more in the long run.

How do Australian summer conditions influence your fabric choices and garment construction across cycling, triathlon and swim?

Obviously, the high UV, particularly in the summer months, is extremely important. Winter is not such a concern, although there are certain apparel items where we might consider needing thicker fabrics, base layers or outerwear options.

At the core of it, it’s really about coping with the heat and UV here in Australia. Unlike northern hemisphere brands who do not have to prioritise exposure to the sun, that’s imperative for us as a brand. We look at fabrics that are breathable and perform well by moisture-wicking to help you stay fresh. We try to balance the garment’s performance in our tough climate conditions with the fit and feel on the body.

What role do athletes play in shaping SCODY’s designs, and how early do they get involved in the development process?

I work with quite a lot of athletes through the ambassador program, and coaches or contacts putting out calls for wear testers. During the development process, we have multiple rounds of testing where we try to test every single garment.This involves them trying garments on to both check sizing and performance in their sporting endeavours. It’s important to get different body shapes, sizes, and get good representation of our market testing products.. Scody caters for aspiring youth athletes all the way through to mature aged athletes, who will have different physiques. We value all constructive feedback from athletes wearing our gear to help us keep improving.

How do you balance aerodynamics and performance with comfort, especially for athletes training or racing in long, hot sessions?

It comes down to fabric, shape and fit. You've got to look at the raw materials you're using. There is a lot of science and research going into that area in general, how can you shave time off your bike ride and stay cool and comfortable. High performance fabrics have changed triathlon and cycling apparel in the last 15 years. We try to learn from wind tunnel, athlete and raw material testing in the design process to create garments that will help you perform your best.

Can you walk us through how a fabric goes from concept to being used in a finished SCODY garment? What has to pass your test before it makes the cut?

Because we don't operate on a traditional retail model (we instead MTO – made to order and do custom clothing for groups), for us to add a new fabric to the range is a big decision. The fabric needs to be an improvement on an existing one or offer new features or benefits for the wearer. We consider the fabric’s purpose, is it for sublimation, is it for plain contrast, what physical and performance properties do we need it to have. These might be hydrophobic, moisture management, UPF or other physical properties.

Sustainability is an ongoing focus at SCODY. How does that influence the way you design, source fabrics, and approach production?

Our MTO made to order system helps us on this path, we’re not holding a warehouse full of stock that people might or might not want, it makes SCODY really unique. I'm really proud we can do that here and stay true to that model.

Manufacturing locally allows us to see the inherent waste in the garment production process. We can strive to reduce or eliminate waste and streamline our process as much as possible. With overseas manufacturing, we never get to see that, it’s all very hidden.

We try to use fabrics with recycled content where possible and those that perform to certain environmental standards.

It’s difficult to avoid polyester and elastane in our industry. We have a relationship with BlockTexx, a local textile recovery business where a majority of our fabric offcuts get recycled. We are also considering the feasibility of trying to take back old garments and recycle them, it's definitely something we hope to implement in the future.

What’s a common misconception athletes have about performance apparel that you wish more people understood?

Not all polyesters are created equal. Invest in good quality clothing and products and they will last longer.

Looking ahead, what excites you most about the future of performance apparel at SCODY?

We’re currently working on revamping our core cycling range, we are trying to elevate the performance jerseys we have and offer some new elite features in that style, whilst catering to the recreational athlete. It’s been exciting to work on that with the team and finesse the finishes. We’re doing wear testing with different athletes, so after we get the feedback, we can get the new style into production.

Shop Australian, Shop SCODY

For Australian-made sportswear that cares about keeping you safe, comfortable, and competitive whilst lending a hand to the local community, shop SCODY today.

Fancy something totally unique? Our amazing design team can help you create something just for you, your teammates, or even for corporate events. Just visit our Design Your Own page to find out more about our custom sportswear.

0 Comments