Behind the Scenes at SCODY: development of new Accelerate triathlon suit

- 17 Oct, 2024

- Home , Craft

- 0 Comments

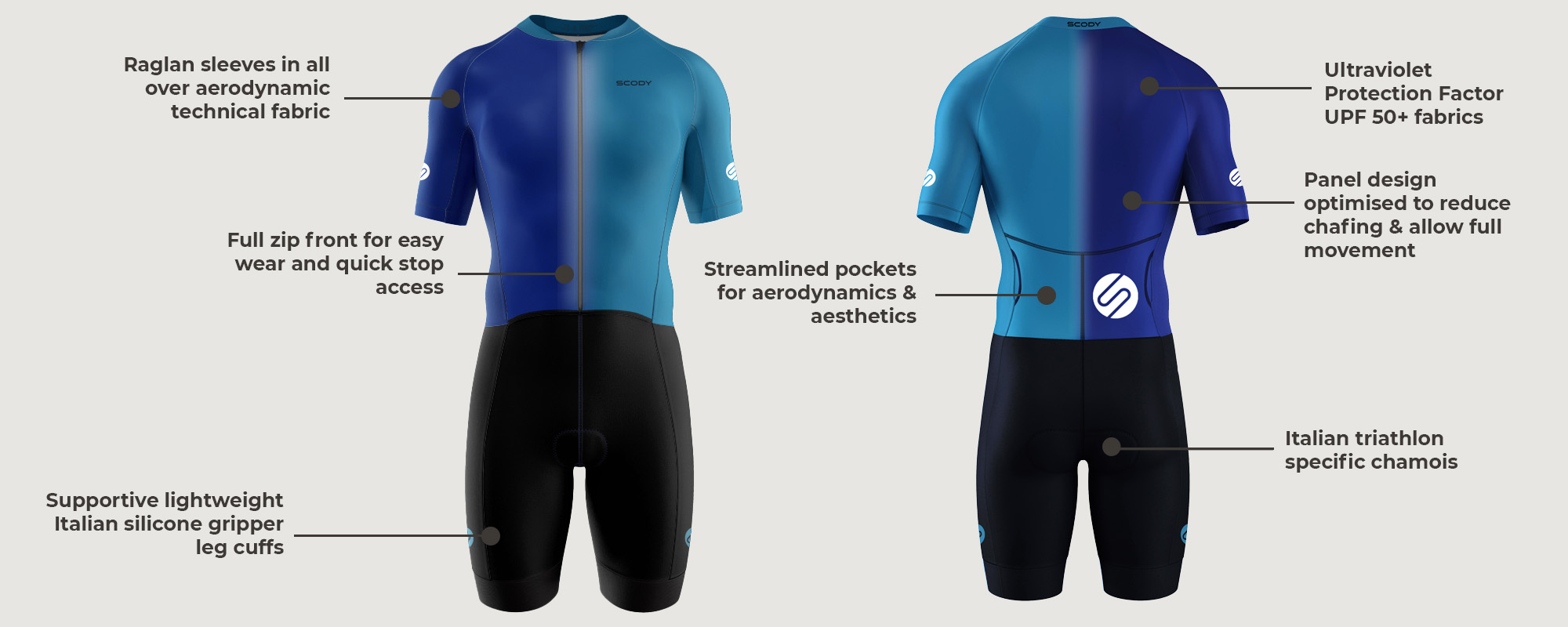

This week SCODY launched our brand new Accelerate Suit. Launching a new suit is no mean feat. You may see the cool new designs but what we see is the months – sometimes years – of research and development, prototyping and testing, amending and improving to finally get to the finished product. When it comes to performance every detail matters: the panel positioning, the sleeves, the fabrics, the stitching and more.

To celebrate the launch of our new suit, we thought we’d give you an insight into just what work goes on behind the scenes before a new garment is released. To that end, we sat down with SCODY’s Pattern Designer, Maylin, who provided answers to all our burning questions about the pattern-making process. Maylin has worked in the apparel industry for over 15 years, working as a pattern maker and garment technician across a diverse range of categories, from technical sportswear to underwear and socks.

Q Why did SCODY develop this suit? How does it differ from previous suits?

- The new Accelerate suit was designed with athlete comfort, performance and sun-protection all in mind.

- We wanted to make a trisuit that was lighter, performed faster and felt more comfortable. We also wanted to elevate the fit, ensuring optimal support and unrestricted movement in necessary areas. We wanted to make a more streamlined, sleek trisuit that made its wearer feel fast and confident.

- We have re-engineered the suit panelling, pockets and other features - balancing fit vs function. We have designed a suit that will protect you in our harsh Australian conditions.

Q Can you walk us through the typical process for creating a pattern from start to finish?

- If we know the intention of the garment, we would generally start with a technical sketch for review.

- We would review and select fabrics and trims for the initial sample and order any new fabrics as required.

- Where possible we would use an existing garment in a similar fabric to use as reference for the first pattern

- We have inhouse pattern making software so we can control the panelling / design / fitting on the body (unlike many other companies where this is done overseas in a 'black box')

- In terms of time involved, it really depends on the garment. For these new suits like the Accelerate suit it has been a longer process with over 8 months of development and testing for the women’s and men’s suits. This consisted of 4 rounds of sampling, with fitting and wear testing done by local athletes.

Q What is involved in selecting fabrics for triathlon suits?

- When selecting fabrics we need to consider the stretch, technical properties (weight, composition wicking etc), ability to sublimate, performance of the fabric across all three disciplines.

- For the Accelerate Suit, we have paired European hydrophobic, technical fabrics and trims, along with Asian recycled polyester (with wicking and anti-bacterial finish) and all-over structure fabric on the sleeves for aerodynamic benefits.

- What sort of testing and prototyping do patterns go through in order to refine the fit and performance of a suit in the final design?

- Usually for any small garment changes on established garments, we make the pattern changes in house and then make a development sample to test those changes. Depending on the complexity, we may have to make several samples to get the fit right.

Q What role does athlete feedback play in tweaking the pattern, and how do you incorporate their insights into the final design?

- Athlete feedback is pivotal during the development of such technical apparel. They are the ones who can guide us as to what is comfortable or irritating, what they prefer or don't! We need to take all of this and consider their body type / measurements and ensure we're balancing that for our base size fitting.

- It is also important to ensure our garments fit all athletes no matter their shape or size. During the development process we strive to fit our garments on a range of athletes of different shapes and sizes. There are some critical points (like leg openings) that we pay special attention to during wear testing too.

Q What are other challenges involved in the pattern making process?

- Being a local manufacturer we have to balance design vs manufacturing challenges that other companies who manufacture overseas may not face. This also makes us really agile and quick to market though. During the sampling process, we can design a new style and get is printed and cut and off to our local sewers in a day. That's definitely something unique that we're really proud of here at SCODY.

We hope you’ve enjoyed learning more about SCODY’s pattern development process. You can shop our new triathlon suits for men here and women here.

Have any more questions about our pattern-making process? Let us know in the comments below! We’d love to hear from you.

0 Comments